- Home

- About Us

- Automation

- Industrial

- Pumps

- Gallery

- Contact

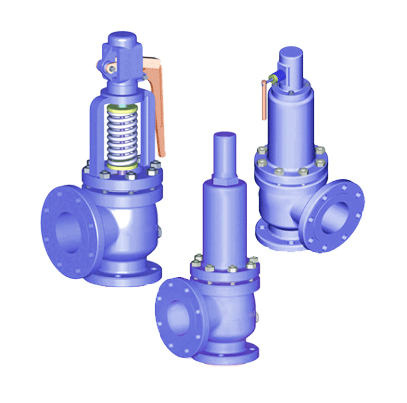

SAFETY / PRESSURE RELIEF VALVE MANUFACTURER IN AHMEDABAD, GUJARAT, INDIA

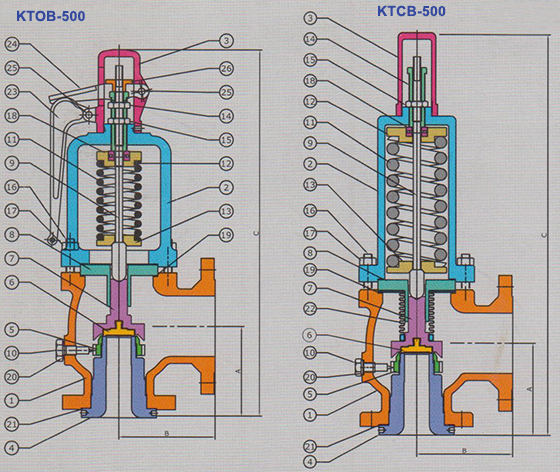

"K-TECH - Series KTFC-500" SAFETY/PRESSURE RELIEF VALVES are designed and manufactured in compliance with API 520 / ASME Section VIM - Division I for High performance application for use on vapor, gas and liquid for over pressure* protection. This conventional Safety / Pressure Relief Valves are versatile, safe & interchangeable.

"K-TECH - Series KTFC-500" SAFETY/PRESSURE RELIEF VALVES are designed and manufactured in compliance with API 520 / ASME Section VIM - Division I for High performance application for use on vapor, gas and liquid for over pressure* protection. This conventional Safety / Pressure Relief Valves are versatile, safe & interchangeable.

DESIGN FEATURES & BENEFITS :

- Rugged Construction

- Replaceable Nozzle & Easy maintenance procedure

- Soft seating arrangement for tight shut-off

- Stellited trims for High Pressure and Temperature

- High Efficiency And Better Performance

- The material selection of guiding components with self aligning disc ensure no gailing of guiding surface.

- High Efficiency Spring

APPLICABLE CODE/ STANDARDS:

- ASME BPVC Section VIII Division I

- API 520/API526/API527

- ASMEB 16.34

- ASMEB 16.5

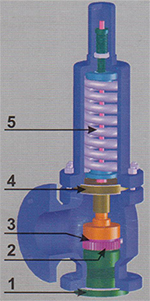

( 1 ) Nozzle Design :- The Nozzle is Pressure parts & in continuously contact with the flow media in both the condition, it so design and : attached with the body to avoid transmission of pipe stresses to the contact surface.

( 2 ) Adjustable Blow Down : The blow down or reset pressure can be simply adjusted to meet the special or specific performance requirements by means of a single adjusting ring.

( 3 ) Trims : Specific trims design & precise machined components are ensures the performance of the valve under critical applications without trouble free long life.

( 4 ) Guiding Area : The material selection of guiding components, together with a self-aligning disc and spindle pivot point, ensures correct alignment and no gelling of guiding surface

( 5 ) High Performance Spring : Design accuracy and selection of spring ensure the repeat-ability of the set pressure. Bellows: Ensure correct valve performance under difficult back pressure conditions.

Seat Leakage integrity : Selection of nozzle and disc materials with precise lapping gives positive shutoff comply with relevant standard and prevents loss of flow media.

TECHNICAL DATA:

- Conventional

- Metal seat

- Sizes: from 1/2" to 10"

- Material: Carbon, alloy, stainless steel and Super alloy Steel.

OPTIONAL FEATURES:

- Soft seating arrangement for tight shut-off

- Open bonnet till L orifice

- Packed Lever

- Test Gag

- Bellows arrangement to prevent back pressure effect

MATERIAL SPECIFICATION

| Sr. No | PART NAME | MATERIAL |

|---|---|---|

| 1 | JBODY | ASTM A216 GR.WCB |

| 2 | BONNET | ASTM A351 GR.CF8/CF8M/WCB |

| 3 | CAP | ASTM A216 GR.WCB/SG IRON |

| 4 | NOZZEL | ASTM A351 GR.CF8/CF8M/CA 15 |

| 5 | NOZZLE RING | ASTM A3S1 GR.CF8/CF8M |

| 6 | DISC | SS 304/SS 316 /SS 410 |

| 7 | DISC HOLDER | ASTM A351 GR.CF8/CF8M |

| 8 | GUIDE | ASTM A351 GR.CF8/CF8M |

| 9 | STEM | SS 304/SS 316/SS 410 |

| 10 | LOCK SCREW | SS 304/SS 316 /SS 410 |

| 11 | SETTING SPRING | SS 304/SS 316/ALLOY STEEL |

| 12 | UPPER SP. WASHER | M.S./SS 304/SS 316 |

| 13 | LOWER SP. WASHER | M.S./SS 304/SS 316 |

| 14 | ADJUSTING SCREW | SS 304/SS 316/SS 410 |

| 15 | ADJ. SCREW NUT | SS 304/SS 316/SS 410 |

| 16 | STUDS | H.T./SS 304/SS 316 |

| 17 | NUTS | H.T./SS 304/SS 316 |

| 18 | THRUST BEARING | STANDARD |

| 19 | GASKET (BODY) | CAF/GRAPHITE/PTFE |

| 20 | GASKET (LOCK SCREW) | CAF/GRAPHITE/PTFE |

| 21 | GASKET (NOZZLE) | CAF/GRAPHITE/PTFE |

| 22 | BELLOW(KTCB500) | SS 316/SS 316L/INCONEL |

| 23 | LEVER | ASTM A216 GR.WCB/SG IRON |

| 24 | FORK | ASTM A216 GR.WCB/SG IRON |

| 25 | LEVER &FORK PIN | M.S./SS 304/SS 316 |

| 26 | STEM NUT | M.S./SS 304/SS 316 |

DIMENSION (mm)

| VALVE SIZE (mm) INLET x OUTLET | A±30 | B±3.0 | c±25,0 | Approx Weight (Kg) |

|---|---|---|---|---|

| 25x50 | 105 | 115 | 456 | 18 |

| 40x50 | 124 | 120 | 490 | 23 |

| 40x80 | 126 | 124 | 560 | 28 |

| 50x80 | 133 | 124 | 575 | 32 |

| 80x100 | 155 | 165 | 674 | 62 |

| 100x150 | 181 | 229 | 930 | 130 |

| 150x200 | 240 | 241 | 1180 | 210 |

| 150x250 | 240 | 266 | 1180 | 250 |

| 200 x 250 | 276 | 280 | 1370 | 325 |

| 250x350 | 385 | 395 | 1600 | 950 |